In terms of maintaining your vehicle's performance, focusing on the idle air control valve is crucial. This tiny but important component has a critical role in controlling engine idle speed by governing the amount of air that flows into the engine when the throttle is shut. A defective idle air control valve can lead to a variety of issues, from erratic idling to engine stalls, making it essential for drivers to detect the signs that show a need for repair.

Knowing when to swap out your idle air control valve can save you time, money, and the frustration of unexpected failures. Whether you're facing trouble starting your vehicle, observing inconsistent idle, or experiencing poor fuel efficiency, these indicators may point to a malfunctioning valve. In this tutorial, we will discuss the typical signs of a failing idle air control valve and provide you with all the information you need to ensure your vehicle functions well.

Understanding the IAC Valve

The idle air control valve, commonly known as the IAC, is a essential component in your vehicle's engine management system. It regulates the level of air that bypasses the throttle plate, making sure the engine holds a steady idle speed when the vehicle is not in motion. This is notably crucial for fuel efficiency and seamless vehicle operation.

When the engine is not warm, the IAC valve allows more air to enter, which aids in raising the idle speed for optimal engine performance during startup start. As the engine warms up, the valve modifies to let in less air, stabilizing the idle speed. A properly working idle air control valve adds greatly to overall engine capability and responsiveness.

However, like any mechanical part, the idle air control valve can degrade or become contaminated over time. Symptoms of a malfunctioning IAC valve are rough idling, stoppping, or an unpredictable idle speed. Identifying these signs early can help you determine when it is time for a change to keep your vehicle's efficiency and effectiveness.

Indicators of a Malfunctioning IAC Valve

One of the most evident signs of a malfunctioning idle air control valve is erratic idle speed. If your vehicle's engine revs up and down while idling or if it stalls unexpectedly, it could suggest that the idle air control valve is malfunctioning. This erratic behavior often leads to an unstable engine performance and can make driving uncomfortable.

Another common symptom is a uneven engine idle. When the idle air control valve stops working, it might be unable to manage the air entering the engine correctly. As a result, the engine may sound rough, or you may feel vibrations when stopped in traffic or at a stoplight. This instability can be accompanied by a reduction in overall engine performance, hindering your ability to drive smoothly.

Additionally, if you find poor acceleration, this may also be connected to a malfunctioning idle air control valve. When the valve is unable to adjust the airflow correctly, it can restrict the engine's response when you press the gas pedal. If you notice that your vehicle hesitates or struggles to gain speed, it is crucial to have the idle air control valve assessed and possibly replaced. spintax ### Step-by-Step Substitution Procedure

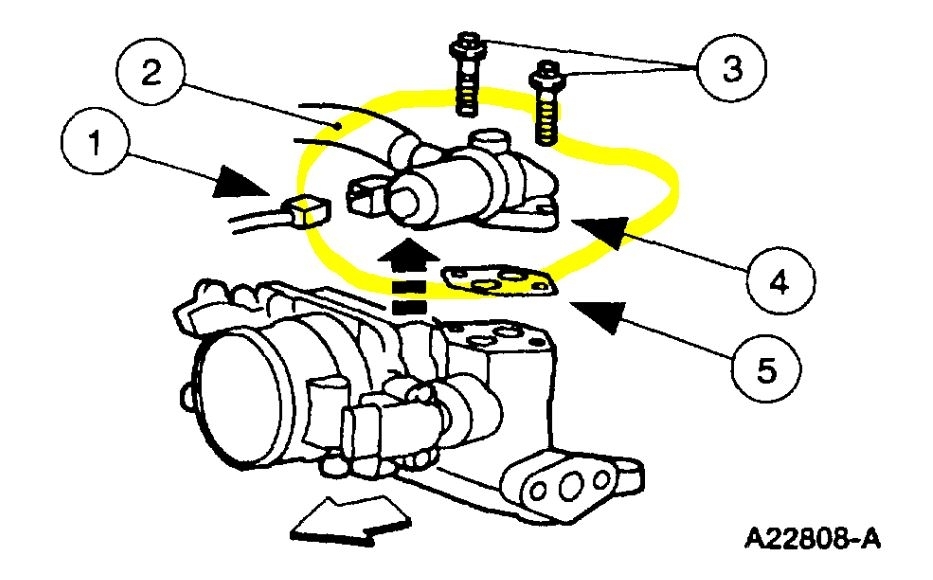

Start the substitution process by making sure your vehicle is parked on a flat surface with the engine turned off and cooled down. Unplug the negative battery terminal to avoid any electrical shorts while working on the idle air control valve. Find the idle air control valve on the throttle body of your engine; it is usually attached with a couple of screws or bolts. Take note of how it is installed to help with the new valve placement.

Carefully detach the old idle air control valve by unscrewing the attachment points and unplugging any electrical connectors. It's crucial to clean the mounting surface to remove any debris or carbon build-up from the old valve. If your vehicle uses a gasket, ensure you replace it with a new one to ensure a good seal. Place the new idle air control valve in position, reinstall it using the screws or bolts, and plug back in the electrical connectors securely.

Once the new valve is fitted, attach the negative battery terminal and start the engine. Allow it to idle for a few moments to confirm that the new valve is functioning properly. Check any check engine light alerts on your dashboard, and while the engine is running, listen for any unusual noises or irregular idle behavior. If everything appears normal, your idle air control valve replacement is complete, and you can drive your vehicle for a test drive to verify proper operation.